Re-grinding

技術改新で刃物が蘇る

Sawblades are revived by technological innovation.

今まで廃棄が当たり前になっていたユーザー様にも朗報!

Good news for users who used to take disposal for granted!

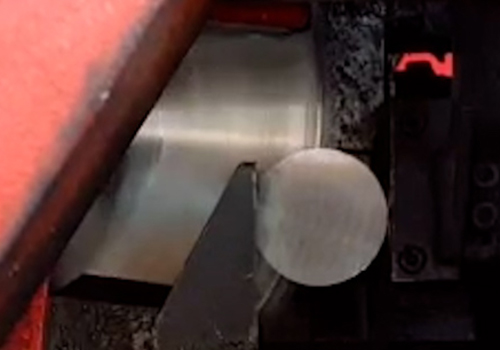

これまで困難とされてきた金属用超硬丸鋸の再研磨や再生が研磨技術、研削盤の発達に伴い高品質の精度を実現することが可能になりました。摩耗、または刃損(チップ欠け)して使用出来なくなった鋸の再研磨・再生し、刃物の寿命が保たれユーザー様の生産向上に貢献します。近年では海外でもチップソーの普及に伴い再研磨事業が注目されています。弊社もアジアをはじめマーケットの開拓に戦略を練って行きたいと思っております。

With the development of grinding technology and grinding machines, it has become possible to achieve high quality precision in the re-grinding and reconditioning of metal carbide circular saws, which had been considered difficult in the past. Re-grinding and reconditioning of saw blades that are worn out or chipped and can no longer be used. Extending blade’s product life and improving users’ productivity. In recent years, the re-grinding business has been attracting attention overseas with the spread of chip saws. We also want to develop strategies for developing markets in Asia and other areas.

チップソー(超硬・ダイヤ・金属用サーメットチップ)の製造には様々な重要な工程があり、それぞれに手練れのエキスパートが万全の体制で製品完成までを繋いでおります。そして工程の最後の決め手となる研磨は各メーカー独自の刃型デザインが最も顕著に現れる重要な部分です。小さな刃先に各社の考え抜かれた研ぎの角度や構成の特徴が詰まっているのです。それは再研磨の分野でも同じで研磨の技術が「新品同様に安心して使用できる」というお客様の更なる信頼に繋がっていきます。

There are various important processes in the manufacture of Tipped saws (Tungsten carbide PCD, Cermet circular for steels), and each of them is connected to the completion of the product by a skilled expert in each process. And the final deciding factor in the process, grinding, is an important part where each manufacturer's unique blade design appears most prominently. The small cutting edge of the blade is packed with the characteristics of each company’s thoughtful grinding angle and composition. It is the same in the field of re-polishing, and the polishing technology leads to increase customer’s confidence that “they can use it as safely as new”.

再研磨の流れ

Re-grinding Flow

営業訪問時・宅配で引き取った鋸の状態を分析し、1)洗浄→2)台金の背取り整形→3)台金の歪み修正→4)チップロー付け(必要時)→5)研磨と新品製作と同等の厳正な管理を行い、お客様のもとへお返しします。

他社製でも自社製と同じく精度維持に努めております。

We analyze the condition of used saws that we receive during our sales visits or by courier, and perform the following procedures: 1) cleaning, 2) shaping of the back of the base metal, 3) correction of the distortion of the base metal, 4) brazing of chips (if necessary), and 5) grinding. The saws are then returned to the customer with the same strict management as for new saws.

We strive to maintain the same accuracy as our own products even if they are made by other manufacturers.

再研磨の時期

Timing to the re-grinding

鋸の切断精度が落ち始めた時や異音、溶着、斜断、カジリなど発生した時などが再研磨のタイミングです。

When the saw's cutting accuracy starts to decline, abnormal noise, welding, diagonal cutting, or galling occurs, etc. it's time to replace it.

| 仕様 Spec |

区分 Category |

素材 Material |

径 Dia |

切断数 Quantity |

|---|---|---|---|---|

| 285x2.0x32hx60z | 新刃 | S35C | 60-62 | 32,986cut |

| 再研磨 | 26,640cut | |||

| 360x2.6x50hx60z | 再研磨 | SCM415 | 70 | 21,783cut |

再生

Reconditioning

外径580ø~以上の大径鋸に限り再生(刃先チップの総付け替え)が可能です。

Reconditioning (total replacement of cutting edge tips) is possible only for large diameter saws with an outside diameter of 580ø or more.

再生の特徴

Benefit for Reconditioning

- ◆刃先チップを新たに付け替えるので品質は新品同等に保たれます。

(台金の曲がりや歪みなどの異常を取り除いたうえで)Since the cutting edge tips are newly replaced, the quality is maintained at the same level as new.

(Abnormalities such as bends and distortions of the base metal will be removed.) - ◆高額な大型鋸の新品導入が回避されるので大きなコスト削減が実現します。

A large cost reduction can be realized by avoiding the introduction of new, expensive large-diameter saws.

※再研磨や再生の評価はお客様の使用状況や鋸の個体差で変わることがあります。

再研磨・再生のご相談はお気軽にお問い合わせください。